ASTM A333 is the Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature Service.

ASTM A333 standard covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. ASTM A333 alloy pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation. All seamless and welded pipes shall be treated to control their microstructure. Tensile tests, impact tests, hydrostatic tests, and nondestructive electric tests shall be made in accordance to specified requirements.

Scope of ASTM A333

This specification covers nominal (average) wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. Several grades of ferritic steel are included as listed in Table 1. Some product sizes may not be available under this specification because heavier wall thicknesses have an adverse affect on low-temperature impact properties.

Supplementary Requirement S1 of an optional nature is provided. This shall apply only when specified by the purchaser.

The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

Note 1: The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as “nominal diameter”, “size”, and “nominal size”.

Mechanical

Required Markings on

Ordering

ASTM A333 standard covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. ASTM A333 alloy pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation. All seamless and welded pipes shall be treated to control their microstructure. Tensile tests, impact tests, hydrostatic tests, and nondestructive electric tests shall be made in accordance to specified requirements.

ASTM A333 Specification for Seamless and Welded Steel Pipe for Low-Temperature Service. Our products for ASTM A335 alloy steel pipes have been listed as follows:

|

|

Scope of ASTM A333

This specification covers nominal (average) wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. Several grades of ferritic steel are included as listed in Table 1. Some product sizes may not be available under this specification because heavier wall thicknesses have an adverse affect on low-temperature impact properties.

Supplementary Requirement S1 of an optional nature is provided. This shall apply only when specified by the purchaser.

The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

Note 1: The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as “nominal diameter”, “size”, and “nominal size”.

Strike temperature condition:

| Crade | The lowest temperature for strike test | |

| ℉ | ℃ | |

| ASTM A333 Grade 1 | -50 | -45 |

| ASTM A333 Grade 3 | -150 | -100 |

| ASTM A333 Grade 4 | -150 | -100 |

| ASTM A333 Grade 6 | -50 | -45 |

| ASTM A333 Grade 7 | -100 | -75 |

| ASTM A333 Grade 8 | -320 | -195 |

| ASTM A333 Grade 9 | -100 | -75 |

| ASTM A333 Grade 10 | -75 | -60 |

Mechanical requiremnts of ASTM A333 alloy pipe

| Standard | Grade | Tensile Strength (MPa) | Yield Point (MPa) | Elongation (%) | |

| Y | X | ||||

| ASTM A333 | Grade 1 | ≥380 | ≥205 | ≥35 | ≥25 |

| Grade 3 | ≥450 | ≥240 | ≥30 | ≥20 | |

| Grade 4 | ≥415 | ≥240 | ≥30 | ≥16.5 | |

| Grade 6 | ≥415 | ≥240 | ≥30 | ≥16.5 | |

| Grade 7 | ≥450 | ≥240 | ≥30 | ≥22 | |

| Grade 8 | ≥690 | ≥515 | ≥22 | ||

| Grade 9 | ≥435 | ≥315 | ≥28 | ||

| Grade 10 | ≥550 | ≥450 | ≥22 | ||

| Grade 11 | ≥450 | ≥240 | ≥18 | ||

Chemical Composition (%) of ASTM A333 steel pipe

| Standard | Grade | Chemical Composition (%) | ||||||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V | Al | ||

| ASTM A333 | Grade 1 | ≤0.30 | 0.40-1.06 | ≤0.025 | ≤0.025 | |||||||

| Grade 3 | ≤0.19 | 0.18-0.37 | 0.31-0.64 | ≤0.025 | ≤0.025 | 3.18-3.82 | ||||||

| Grade 4 | ≤0.12 | 0.18-0.37 | 0.50-1.05 | ≤0.025 | ≤0.025 | 0.44-1.01 | 0.47-0.98 | 0.40-0.75 | 0.04-0.30 | |||

| Grade 6 | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.025 | ≤0.025 | |||||||

| Grade 7 | ≤0.19 | 0.13-0.32 | ≤0.90 | ≤0.025 | ≤0.025 | 2.03-2.57 | ||||||

| Grade 8 | ≤0.13 | 0.13-0.32 | ≤0.90 | ≤0.025 | ≤0.025 | 8.40-9.60 | ||||||

| Grade 9 | ≤0.20 | 0.40-1.06 | ≤0.025 | ≤0.025 | 1.60-2.24 | 0.75-1.25 | ||||||

| Grade 10 | ≤0.20 | 0.10-0.35 | 1.15-1.50 | ≤0.03 | ≤0.015 | ≤0.15 | ≤0.25 | ≤0.015 | ≤0.50 | ≤0.12 | ≤0.06 | |

| Grade 11 | ≤0.10 | ≤0.35 | ≤0.6 | ≤0.025 | ≤0.025 | ≤0.50 | 35.0-37.0 | ≤0.50 | ||||

Referenced Documents

- A370 Test Methods and Definitions for Mechanical Testing of Steel Products

- A671 Specification for Electric-Fusion-Welded Steel Pipe for Atmospheric and Lower Temperatures

- A999/A999M Specification for General Requirements for Alloy and Stainless Steel Pipe

- E23 Test Methods for Notched Bar Impact Testing of Metallic Materials

Heat Treatment Requirements

| P5, P9, P11, and P22 | |||

| Grade | Heat Treatment Type | Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering Temperature Range F [C] |

| P5 (b,c) | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| Subcritical Anneal (P5c only) | ***** | 1325 - 1375 [715 - 745] | |

| P9 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P11 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1200 [650] | |

| P22 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P91 | Normalize and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Quench and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

Chemical Requirements

| Grade | P-5 | P-9 | P-11 | P-22 | P-91 | P-91 shall also include the following: | ||

| Element | UNS Designation | K41545 | S50400 | K11597 | K21590 | K91560 | ||

| Carbon | 0.15 max | 0.15 max | 0.05 - 0.15 | 0.05 - 0.15 | 0.08 - 0.12 | V at 0.18 - 0.25 | ||

| Manganese | 0.30 - 0.60 | 0.30 - 0.60 | 0.30 - 0.60 | 0.30 - 0.60 | 0.30 - 0.60 | N at 0.030 - 0.070 | ||

| Phosphorous, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.020 | Ni at 0.40 max | ||

| Sulfur, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.010 | Al at 0.02 max | ||

| Silicon | 0.50 max | 0.25 - 1.00 | 0.50 - 1.00 | 0.50 max | 0.20 -0.50 | Cb at 0.06 - 0.10 | ||

| Chromium | 4.00 - 6.00 | 8.00 - 10.00 | 1.00 - 1.50 | 1.90 - 2.60 | 8.00 - 9.50 | Ti at 0.01 max | ||

| Molybdenum | 0.45 -0.65 | 0.90 - 1.10 | 0.44 - 0.65 | 0.87 - 1.13 | 0.85 - 1.05 | Zr at 0.01 max | ||

Tensile Requirements

| Seamless | ||||||||

| P-5 | P-9 | P-11 | P-22 | P-91 | P91 shall not have a hardness not exceeding 250 HB/265 HV [25HRC]. | |||

| Tensile Strength, min., psi | ||||||||

| ksi | 60 | 60 | 60 | 60 | 85 | |||

| MPa | 415 | 415 | 415 | 415 | 585 | |||

| Yield Strength, min., psi | ||||||||

| ksi | 30 | 30 | 30 | 30 | 60 | |||

| MPa | 205 | 205 | 205 | 205 | 415 | |||

Permissible Variation in Wall Thickness

| NPS [DN] Designator | Tolerance, % from Specified | |||

| Over | Under | |||

| 1/8 to 2 1/2 [6 to 65] incl., all t/D ratios | 20.0% | 12.5% | ||

| Above 2 1/2 [65], t/D < or = 5% | 22.5% | 12.5% | ||

| Above 2 1/2 [65], t/D > 5% | 15.0% | 12.5% | ||

| (t = Specified Wall Thickness; D = Specified Outside Diameter) | ||||

Elongation Requirements

| Calculated Minimum Elongation Values | |||||

| Elongation in 2 in. or 50 mm, min % | |||||

| Wall Thickness | P5, P9, P11, P22 | P91 | |||

| in. | mm | Longitudinal | Transverse | Longitudinal | |

| 5/16 (0.312) | 8 | 30 | 20 | 20 | |

| 9/32 (0.281) | 7.2 | 28 | 19 | 19 | |

| 1/4 (0.250) | 6.4 | 27 | 18 | 18 | |

| 7/32 (0.219) | 5.6 | 26 | 17 | ||

| 3/16 (0.188) | 4.8 | 24 | 16 | ||

| 5/32 (0.156) | 4 | 22 | 15 | ||

| 7/8 (0.125) | 3.2 | 21 | 14 | ||

| 3/32 (0.094) | 2.4 | 20 | 13 | ||

| 1/18 (0.062) | 1.6 | 18 | 12 | ||

Permissible Variations in Outside Diameter

Outside Diameter at any point shall not vary from standard specified more than:

| NPS [DN] Designator | Over | Under | ||

| in. | mm | in. | mm | |

| 1/8 to 1 1/2 [6 to 40], incl. | 1/64 (0.015) | 0.40 | 1/64 (0.015) | 0.40 |

| Over 1 1/2 to 4 [40 to 100], incl. | 1/32 (0.031) | 0.79 | 1/32 (0.031) | 0.79 |

| Over 4 to 8 [100 to 200], incl. | 1/16 (0.062) | 1.59 | 1/32 (0.031) | 0.79 |

| Over 8 to 12 [200 to 300], incl. | 3/32 (0.093) | 2.38 | 1/32 (0.031) | 0.79 |

| Over 12 [300] | +/- 1% of the specified outside diameter | |||

Mechanical

Tests Specified

| Transverse or Longitudinal Tension Test and Flattening Test, Hardness Test, or Bend Test | ||||||||

| For material heat treated in a batch-type furnace, tests shall be made on 5% of the pipe from each treated lot. For small lots, at least one pipe shall be tested. | ||||||||

| For material heat treated by the continuous process, tests shall be made on a sufficient number of pipe to constitute 5% of the lot, but in no case less than 2 pipe. | ||||||||

| Notes for Hardness Test: | P91 shall not have a hardness not exceeding 250 HB/265 HV [25HRC]. | |||||||

| Notes for Bend Test: | For pipe whose diameter exceeds NPS 25 and whose diameter to wall thickness ratio is 7.0 or less shall be subjected to the bend test instead of the flattening test. | |||||||

| Other pipe whose diameter equals or exceeds NPS 10 may be given the bend test in place of the flattening test subject to the approval of the purchaser. | ||||||||

| The bend test specimens shall be bent at room temperature through 180 without cracking on the outside of the bent portion. | ||||||||

| The inside diameter of the bend shall be 1 inch [25 mm]. | ||||||||

| Hydrostatic Test | Each length of pipe shall be Hydro tested, at option of manufacture, nondestructive electric testing can be used. | |||||||

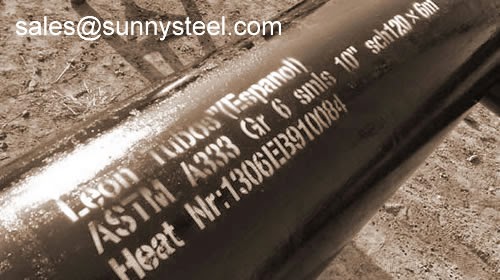

Required Markings on

Each Length

(On Tags attached to each Bundle in case of Bundled Pipe) Markings will adhere to prescribed specifications in A 999/A999M and be: Rolled, Stamped, or Stenciled (Mfrs. Option)

| In addition, markings will include: | ||||||||||||||||||||||||||

| Length of pipe |

| |||||||||||||||||||||||||

| Schedule Number | ||||||||||||||||||||||||||

| Heat Number or Manufacturer's number by which heat can be identified | ||||||||||||||||||||||||||

| An Additional Symbol "S" if the pipe conforms to any Supplementary Requirements | ||||||||||||||||||||||||||

| S1 - Product Analysis | ||||||||||||||||||||||||||

| S2 - Transverse Tension Test | ||||||||||||||||||||||||||

| S3 - Flattening Test | ||||||||||||||||||||||||||

| S4 - Metal Structure and Etching Tests | ||||||||||||||||||||||||||

| S5 - Photomicrographs | ||||||||||||||||||||||||||

| S6 - Photomicrographs for Individual Pieces | ||||||||||||||||||||||||||

| S7 - Alternative Heat Treatment - Grade P91 | ||||||||||||||||||||||||||

| Pipe that has been weld repaired shall be marked "WR". | ||||||||||||||||||||||||||

Reference Documents

- ASTM A999/A 999M Specification for General requirements for Alloy and Stainless Steel Pipe.

- ASTM E 213 Practice for Ultrasonic Examination of metal Pipe and Tubing

- ASTM E 309 Practice for Eddy-Current Examination of Steel Tubular Products Using Magnetic Saturation

- ASTM E 381 Method of Macroetch testing Steel Bars, Billets, Blooms, and Forgings

- ASTM E 570 Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products

- ASME B26.10M Welded and Seamless Wrought Steel Pipe

Ordering

Information

Orders for material under this specification should include the following, as required, to describe the desired material adequately:

| Quantity | Feet, meters, or number of lengths |

| Name of material | Seamless Alloy Steel Pipe |

| Grade | P5, P9, P11, P22, P91 |

| Manufacture | Hot-finished or cold-drawn |

| Size using one of the following: | |

| NPS and Schedule Number | |

| Outside Diameter and Nominal Wall Thickness | |

| Outside Diameter and Minimum Wall Thickness | |

| Inside Diameter and Nominal Wall Thickness | |

| Inside Diameter and Minimum Wall Thickness | |

| Length | Specific or Random |